Some Singapore hospitals tap technology to save time, reduce manpower and cost

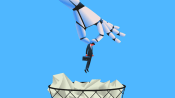

They are saving tens of thousands of man-hours each year through automation and robots.

A digital system at SGH allows the team to track and trace sterile instruments quickly and deliver them to surgeons.

This audio is generated by an AI tool.

SINGAPORE: With a simple push of a button and a touch on a screen, dozens of body tissue samples can be processed at once by a machine at a laboratory at Tan Tock Seng Hospital (TTSH).

Traditionally, lab staff do the work by hand, spending hours processing hundreds of samples a day.

TTSH is the first healthcare institution in Singapore to introduce such an automated system that processes bacteria which can cause infections.

The lab has become more productive despite increasing workload, said Dr De Partha Pratim, senior consultant in the hospital’s Department of Laboratory Medicine.

“Overall, the system has produced savings in time (and) effort, and that means we can get results out faster, which enables the system as a whole to function more quickly. And we are less of a bottleneck for the rest of the hospital.”

“With a rising workload, which goes up every year by about 4 or 5 per cent, we haven't had to employ new staff to do the work. The automation has absorbed that workload while still keeping the turnaround time,” he added.

USING TECH TO SAVE TIME

TTSH is among some hospitals here that are saving tens of thousands of man-hours each year by tapping technology, such as automation and robots.

This has helped them to ease the manpower crunch faced by the healthcare sector, and lower operating costs for the hospital.

Meanwhile, Singapore General Hospital (SGH) has introduced a digital instrument tracking system that helps staff ensure surgical supplies are clean and safe for use in operating theatres. With this, staff log and trace equipment instead of using pen and paper.

After a piece of equipment has been cleaned, staff can easily identify what set it belongs to and pack them all together. It has helped the hospital save nearly 2,000 man-hours for this job per month.

Relieved of this tedious task, staff morale is higher as they can now spend their time on higher-value tasks, said the hospital's deputy director of nursing Goh Meh Meh.

The hospital generates about 25,000 sets of sterile instruments per month, she said.

“It's quite an uphill task for the staff to maintain. And sometimes in operating rooms, they need an instrument very urgently. So from the system, we are able to track and trace quickly and identify the sets and deliver them in a timely manner to our surgeons."

ADOPTING AN AUTOMATED CENTRAL SYSTEM

Besides surgical instruments, it is also important to ensure equipment like needles and bandages are delivered to the right places, at the right time.

SGH has been using automation to improve efficiency of its deliveries. A centralised system receives orders from various users in the hospital, picks out what is needed and delivers it to the required station for staff to double check.

Before using automation, around a dozen employees would have to work 10-hour shifts daily to meet this demand. But now, just three team members are required to do this, at just half the time.

The system has also helped the hospital determine optimal use of the supplies, and timely replenishments.

"We don't have to carry a lot of stocks and so the overall picture, there's a lower operating cost for the hospital. And of course, there will be some recovery and that's where the patient cost will have some advantages,” said assistant director of SGH’s supply chain department, Mr Rosli Boedjang.

Reducing stock also means that the warehouse does not need to store as many items and the space is used better, he said.